Strauch Fiber Equipment Co.

We Handcraft It All With You In Mind.

Ball Winder FAQ

Click on your question below and you will be directed to the answer.

How do I prevent the yarn from slipping off the ball?

Routine maintenance?

What is the proper height of the yarn guide?

Why does the base wobble?

I've lost some of the little feet on the base. Can I get replacements?

How can I prevent the red handle from coming off?

How do I keep the clear plastic cone from coming off?

How do I pull the yarn off the Swift while winding a ball?

Can I purchase replacement belts?

What upgrades are available for the Strauch Jumbo Ball Winder?

Can obsolete Fricke ball winders be upgraded?

I have an older ball winder, how do I stop making poorly shaped balls?

Routine maintenance?

What is the proper height of the yarn guide?

Why does the base wobble?

I've lost some of the little feet on the base. Can I get replacements?

How can I prevent the red handle from coming off?

How do I keep the clear plastic cone from coming off?

How do I pull the yarn off the Swift while winding a ball?

Can I purchase replacement belts?

What upgrades are available for the Strauch Jumbo Ball Winder?

Can obsolete Fricke ball winders be upgraded?

I have an older ball winder, how do I stop making poorly shaped balls?

How do I prevent the yarn from slipping off the ball?

The problem can be compounded if the ply of the yarn creates a very round yarn. Because the winder spins rapidly, the yarn will slip off the ball while you are winding making it difficult to create a nice looking center-pull ball that pulls effortlessly from the middle.

Viewing the video to the left may help:

If your slippery yarn still doesn't work well on our winder we recommend a few alternatives.

You can, of course, wind the ball by hand. But..........

If you want to use the ball winder, and you don't mind going VERY slowly, put some stiff paper or a toilet paper core on the winder before you begin winding. When you remove the ball, take the core off with it.

You may want to slip something around the yarn to keep the ball intact until you are ready to use it. To use, put the ball on a lazy kate, a free-standing toilet paper holder, or other device that will let it turn freely. You then wind off the yarn from the outside of the ball.

If you are working with a very fine yarn or if you plan on using the yarn for weaving, winding the yarn onto a large cardboard bobbin with a bobbin winder will allow greater control as you wind from the skein. This will make it much easier to wind your warp with consistent tension, or to wind the bobbins for your shuttles.

Routine maintenance?

What is the proper height of the yarn guide?

Why does the base wobble?

You have two choices.

1. Upgrade to the new clamp design shown on the Pricing page, under categories, ball winder.

2. For those who want to keep their old style clamp, we have an extension that will extend the reach and allow the clamp to hold the winder securely on the table. It easily attaches to their existing clamp and eliminates the wobble. It also works great for folks with round tables that do not have a wood drop down.

To order specify part number: 7125. Price for the clamp extension is $8.00 (includes shipping).

I've lost some of the little feet on the base. Can I get replacements?

How can I prevent the red handle from coming off?

How do I keep the clear plastic cone from coming off?

How do I pull the yarn off the Swift while winding a ball?

Can I purchase replacement belts?

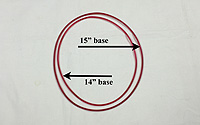

For the newer 15" long base winder, click here: 15" Replacement Belts

For the older 14" models, click here: 14" Replacement Belts

These belts for the 14" base will also fit the old, obsolete Fricke ball winders.

Note: To extend the life of drive belts, remove them from the machine when you are finished for the day.

Does the Strauch Jumbo Ball Winder ever need to be upgraded?

With the older winders, if they are functioning perfectly, nothing needs to be done. As one says: "If it ain't broke....don't fix it!".

Can obsolete Fricke ball winders be upgraded?

These many redesigns of the Jumbo Ball Winder make upgrading old, obsolete Fricke winders no longer economical. Practically all of the components of the winder have been changed. It's like upgrading a 2000 car so it functions like a 2017 model. By the time you spend all the money to do it... it would have been less costly to just buy a new car!

You'll be much more satisfied purchasing a new, fully functional Strauch Jumbo Ball Winder.

I have an older ball winder, how do I stop making poorly shaped balls?

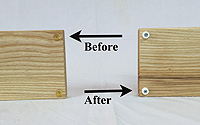

The top photo shows the slipped out bearing.

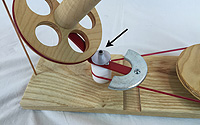

The middle photo shows the way it should look. It's an easy fix. Unscrew the plastic cone to remove the entire winding assembly. Use something flat to push the bearing back into the wood.

To prevent it from again coming out, install a small screw as shown in the bottom photo.