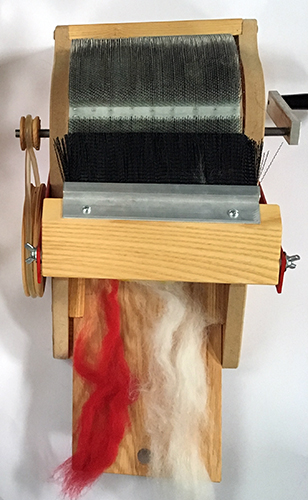

Hi there, I’m Mike Gallagher, the new owner of Strauch Fiber Equipment Co. Right now, I’m learning the ropes and training with Otto and Joanne at their workshop in Virginia. Although they are retiring, they plan on remaining active within the fiber industry and available to me as needed for product improvement and new product development.

We just got back from the Blue Ridge Fiber Festival, where I was able to introduce myself personally to Strauch fans, and I’d like to do the same for everyone else who didn’t make it out to the show, so here goes:

I grew up in Nebraska, attended college in Maine, and have since landed in North Carolina, where I’ve been for about 10 years total (7 years in the Raleigh area and 3 years in Hickory, where I currently live and have been running my business). I love living near the mountains, and I have a 4 year old daughter who keeps me busy outside of the workshop.

I used to focus mostly on custom furniture but have recently moved towards making custom wood components. I have a BFA in Woodworking and Furniture Design from the Maine College of Art and have taken workshops at both the Penland School of Crafts and Haystack Mountain School of Crafts.

Ever since I remember, my mom has done needlepoint, and she had a spinning wheel in the house when I was growing up, so I do have some fiber arts experience! During my first year of college, I took a Shibori class where I ended up sewing and dyeing a simple kimono and many other small test pieces using different resist techniques, and I also encountered lots of “fiber arts moments” while attending art school. More recently, I have been making components and doing some equipment assembly for another company in the fiber arts industry, and have been working with them for a little over 5 years now.

I’ve been looking for an opportunity to expand my business and skillset, but hadn’t quite found anything that fit just yet. So when I learned that Strauch was looking for a successor, it was kind of a light bulb moment since it’s in the realm of work that I’ve currently been doing.

The company size feels like a good next step for business growth, allowing me to keep my hands in the making process. The reputation of the product line and the philosophy that the Strauch’s have built the company around really speak to me, and Otto and Joanne are fantastic to work with. We have a lot in common in terms of how we look at business and life.

I’m looking forward to going to more fiber shows, getting to know retailers and customers, and learning how everything comes together. I’m fascinated with how other people make things and learning this process has been a blast! There is still so much to do, but I’m up for the challenge.

In the future, I have plans to expand the product line. Rest assured, we’ll still approach product improvement and development using the same standards Otto and Joanne have set! There might be small improvements or changes to the existing product line, but most of that I see happening on the manufacturing process side, without changing the key things that make these machines such great products.

I look forward to sharing this journey with you!